ATOS Capsule

Optical Precision Measuring Machine

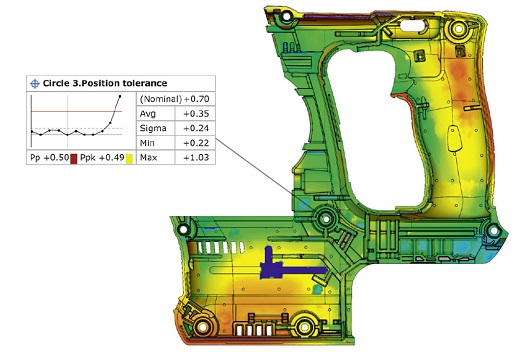

The ATOS Capsule is an optical precision measuring machine (OPMM) for full-field digitization of contoured part geometries. The fringe projection system of the ATOS series is used for production quality assurance of small to medium-sized parts and excels by its high precision for fine details. ATOS Capsule is utilized, for example, for first article inspection of gears, turbine blades and wheels as well as medical parts.

ATOS Capsule in Use

In the standardized measuring machine ATOS ScanBox, the ATOS Capsule is used for fully automated measurement and inspection of contoured parts. Used in ATOS ScanBox Series 4, the ATOS Capsule serves as a mobile and therefore flexible measuring system for small parts. In the ATOS ScanBox models of series 5 and 6, the ATOS Capsule can be extended with a Plus Box photogrammetry add-on. Thus, bigger components or several parts can be measured simultaneously.